Bringing

greater vision

to everyone

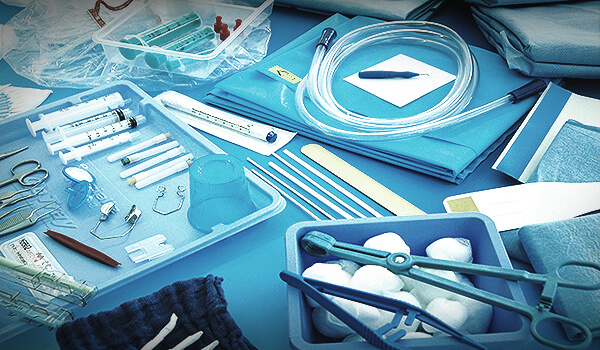

Individuelle OP-Sets in der Ophthalmologie

MED – Ihr Spezialist ist einer der weltweit führenden Hersteller von Abdecksystemen und OP-Sets aus Deutschland. Absolute Qualität, schnell, flexibel und zertifiziert, genau das Richtige für Ihre Operationsräume.

Qualität, 100% Made in Germany

- Eigene Entwicklung, immer „neu”

- Eigene Herstellung, auf neuestem Stand der Technik

- Individuelle OP-Komplettsets: Sie stellen sie zusammen, wir stellen sie her

- Basis-OP-Komplettsets, bewährt seit knapp 20 Jahren

- Zertifiziertes Qualitätsmanagement

- Kürzeste Produktionszeit

- Top Lieferservice